Computerized feeding equipment for sows and weaned pigs installed at the Tidewater AREC’s Swine Research Facility

November 5, 2020

R.T. Niblett[1], A.H. Talmage1, K.A. Williams[2], and M.J. Estienne[3]

[1] Graduate student; [2] Agricultural Supervisor and Swine Unit Manager; [3] Professor and Swine Research Physiologist (send correspondence to mestienn@vt.edu)

In a bygone era, one of the many daily tasks facing a farmer was “slopping the hogs”. Pigs were fed from a bucket a mixture of grains and produce, such as stale bread and melon rinds. Today, diets are much more complex and in addition to corn and soybean meal, contain vitamins and minerals assuring that all of the pig’s nutrient requirements are met. As evident at the Tidewater Agricultural Research and Extension Center (AREC) in Suffolk, even the way that the pigs are “served” their meals has gone high-tech. Indeed, computerized feeding systems have been installed for both breeding sows, and weaned piglets. Both systems allow individual feeding of animals, and data such as amount of feed consumed and body weights are accurately recorded. These technologies will enhance the Tidewater AREC’s research efforts in nutritional methods of enhancing sow reproductive performance, and management systems to increase nursery pig growth performance and welfare. The two feeding systems are briefly described below.

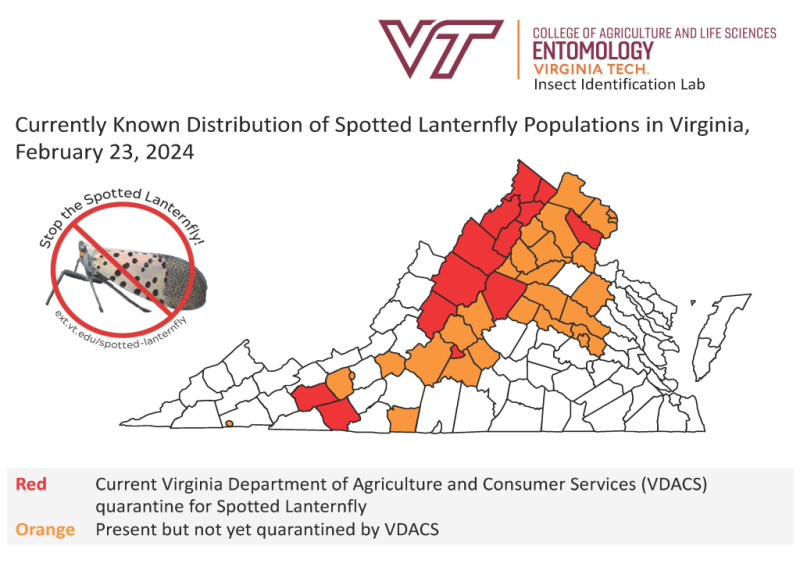

Electronic Sow Feeder (ESF)

The John Lee Pratt Endowment, established to support animal nutrition programs at Virginia Tech, was the source of funds used for the recent purchase of an ESF installed at the Tidewater AREC. The ACCU-TEAM G-Station ESF was manufactured by Osborne Industries in Kansas. Each sow in the breeding herd is fitted with an ear tag that contains a transponder allowing access to a centralized feeding system. When a sow enters the station and places her head in the feed trough, a rear gate is automatically shut, allowing the sow to eat without interference from other animals (Figure 1). The computerized feeding station weighs the sow and delivers the correct amount of feed based on weight, body condition, parity, and stage of gestation. Once the sow finishes her ration, she leaves the station through a side gate and the rear gate automatically opens, allowing access to another sow. The ESF system has software that allows faculty and staff to retrieve individual animal performance data such as body weights and feed intake and if necessary, use an app or laptop to change feed allowance from off-site locations. Thus, this technology is consistent with the College of Agriculture’s SmartFarm Innovation Network initiative.

Figure 1. Electronic sow feeder (ESF) that was recently installed in the breeding-gestation barn at the Tidewater AREC in Suffolk. Each sow is fitted with an ear tag that contains a transponder providing access to feed. Panel A shows a sow entering the feeding station. Once the sow places her head in the feed trough (Panel B), the rear gate closes automatically, preventing other sows from entering. A pre-determined amount of feed is slowly dispensed in the trough, allowing the sow to eat without competition from other animals. Note the scale platform shown at the bottom of Panel B. The sow is automatically weighed as she consumes her feed. As shown in Panel C, the sow has completed her meal and leaves the station through a one-way side door. The rear gate then opens, allowing the next sow to enter the station.

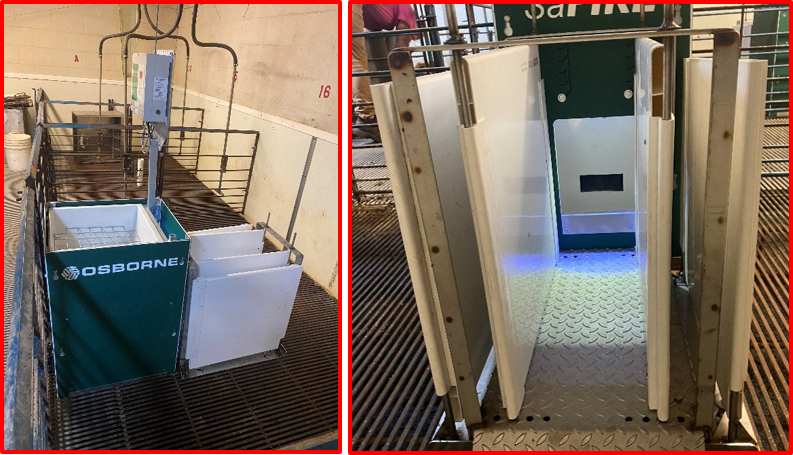

Small Animal Feed Intake Recording Equipment (saFIRE)

Feed Intake Recording Equipment (FIRE) Systems have been used for over 20 years by many swine genetics companies to measure feed intake and other performance characteristics of growing-finishing hogs (70 pounds of body weight and up) in group pens. This helps identify the most efficient animals that are selected to improve herd genetics.

Until now, FIRE systems were only available for larger pigs. However, Osborne Industries is developing the saFIRE, which will allow for the automatic measurement of body weights and feed consumed by individual nursery pigs weighing from 12 pounds to approximately 70 pounds and kept in a group pen. Osborne Industries chose the Tidewater AREC to test the saFIRE and two feeders were recently installed, becoming the first units on University farms in North America (Figure 2).

Using radio frequency identification (RFID) technology, pigs are identified at the saFIRE Station, allowing the system to assign all measurements to individual records. Sensitive load cells continually weigh the animal, the trough and feed. The saFIRE records the time and duration of each unique visit, along with the weight of the animal and feed consumed. The information is transferred to a computer in real-time and can be used to generate reports or studied in relation to environmental, genetic, and nutritional variables.

Figure 2. Small Animal Feed Intake Recording Equipment (saFIRE) recently installed in a nursery room at the Tidewater AREC in Suffolk. Panels that can be adjusted as pigs grow, limit access to the feeder to a single animal at a time. Each pig is fitted with an ear tag containing a transponder that identifies the pig and allows real-time collection of body weight and feed consumption data.